As the name suggests, a vegetable packaging machine is used for packaging vegetables and greens such as lettuce, radishes, green onions, spinach, and other related products. These machines come in various types depending on whether they are for home or industrial use and the level of automation in semi-automatic, and automatic can be ordered, with options to include MAP (Modified Atmosphere Packaging) and vacuum technology and also Manual model.

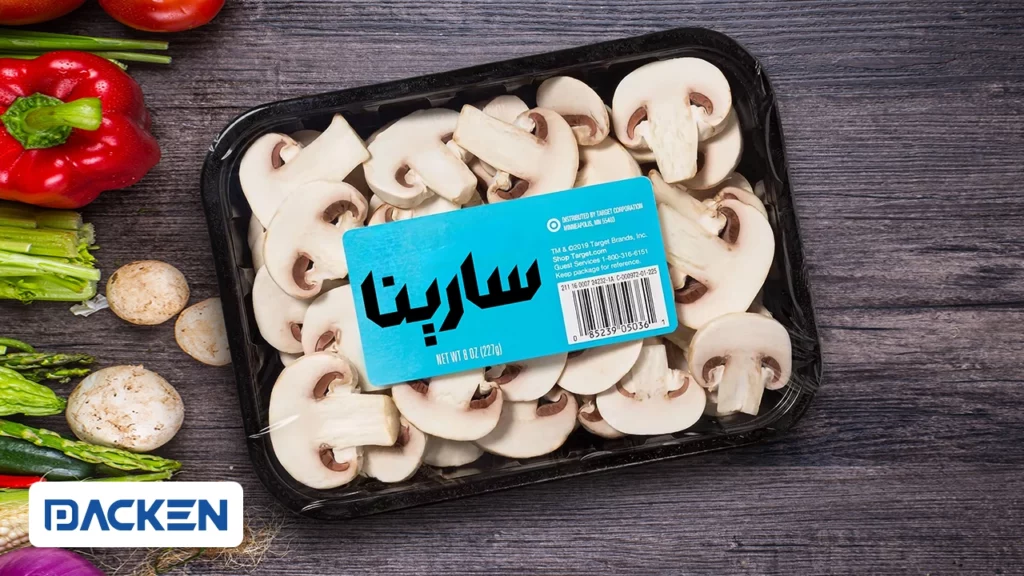

Vegetables can be packaged in various types of containers and materials such as plastic, foil, or cans. Depending on the type of vegetable (fresh, dried, chopped, fried, or frozen), you can choose the appropriate container, type of packaging, and machine. At Packen Company, as a leading manufacturer, we can provide you with the necessary consultation in this field.

How to Increase the Shelf Life of Vegetables

Vegetables are among the most challenging products to package. The packaging of vegetables must prevent the entry of foreign materials, water evaporation, and the respiration of the product to ultimately increase shelf life and preserve their organoleptic properties. To achieve these goals in vegetable packaging, the best method is Modified Atmosphere Packaging (MAP).

Using this method, a specific amount of completely inert gases such as O2 (oxygen), N2 (nitrogen), and CO2 (carbon dioxide) is injected into the packaging. The packaging is then sealed with a permeable membrane. The permeable membrane allows for the replacement of O2 in the package with environmental O2 when it runs out, thereby maintaining a stable level of CO2 within the packaging. This prevents anaerobic respiration and limits aerobic respiration.

The use of a film with a breathable membrane or a breathable film to increase shelf life is recommended if the product is uncut and still respiring. However, if the product is cut, it is possible to use regular films for packaging using the modified atmosphere method.

Automatic Vegetable Packing

Automatic vegetable and greens packing is an industrial process where products are packaged automatically using mechanized machines. This process is used to maintain freshness, prevent spoilage, extend shelf life, preserve product quality, and also for high-capacity packaging.

The automatic vegetable and greens packing process includes several stages:

Washing and Sanitizing: In this stage, vegetables and greens are cleaned of contaminants and unwanted particles. This may involve washing, drying, or using other mechanical methods to remove impurities.

Sorting and Separation: In this stage, vegetables and greens are sorted based on size, shape, color, and quality. Machines automatically separate stones, debris, and unhealthy products.

Cutting and Portioning: If needed, vegetables and greens are cut and portioned according to specific requirements such as size, shape, or weight. This stage is carried out automatically by slicing machines.

Packaging: After the previous stages, vegetables and greens are automatically placed into suitable packaging. Depending on the type of product, volumetric fillers and multi-head weighers can be used. The packaging process can include automatic denester, fillers, automatic rower, jet printers, and traffic table, resulting in a fully automated packing line.

For more detailed information, please contact us.

Types of Vegetable Packing Machines

Depending on the level of automation, whether the machine is manual or automatic, as well as its use for home or industrial applications and the type of vegetable or domestic and international markets, the following types of machines are used for packing:

Types of Packing Machines

- Manual Sealing Machine

- Horizontal Sealing Machine

- Pillow Pack Machine

- Shrink Packing Machine

- Tray Sealer Machine

- Stretch Film Machine

- Weighing Packing Machine

- Vacuum Chamber Machine

- Tabletop Sealing Machine

We will now explain the most important machines mentioned above.

Types of Vegetable Packing Machines

Sealing means to close or seal something, and when talking about sealing in the packaging industry, it refers to placing the product inside a container, then sealing and closing the container. With this brief explanation, we’ll proceed to introduce different types of vegetable and fruit sealing packing machines.

In these machines, products related to vegetables, greens, or other products (depending on the machine’s features) are placed inside containers and manually or automatically positioned in the machine. The machine then automatically put the film over the container and seals it.

Typically, these machines also have additional capabilities such as vacuuming and Modified Atmosphere Packaging (MAP), which can vary depending on the machine’s options. At Packen, we offer unique features on our manufactured machines and have the capability to add custom options according to your needs. For consultation, feel free to contact our experts; we are happy to assist you.

Automatic Tray Sealer Packaging Machine

The operation of this machine is as follows:

Step 1: Pre-formed trays (the shape and material of the tray can vary depending on the product type) are placed on the machine either automatically (using a denester) or manually. The product is then loaded into the trays either automatically or manually (using a filling machine).

Step 2: The trays filled with the product are then directed into the machine’s mold. Necessary adjustments are made to the machine, and then vacuuming, gas injection, and packaging are carried out.

Step 3: After this stage, the packed trays are placed in sequence by an automatic rower so that the jet printer can print the additional information on the packaging.

The Automatic Tray Sealer packaging machine is one of the products manufactured by Packen. Typically, tray sealer machines have the capability to package with or without vacuum, which is adjusted based on the customer’s needs.

Machine Features:

The machine can be easily set up and configured by the operator.

Adjustable for various tray sizes.

Various options available according to customer needs.

Capable of packaging using different methods such as MAP and others.

Applications:

In addition to vegetables and greens, this machine can also package the following items:

- Various dry foods

- Various ready-to-eat cold foods

- Pickled items (such as pickled cucumbers, olives) and pickled vegetables

- Various meat and protein products

- Fruits and various salads

- Packaging of dairy products such as cheese

- Bread and pastries

For more information, you can view the page on the automatic tray sealer packaging machine.

Semi-Automatic Tray Sealer Packaging Machine

The semi-automatic tray sealer has a rotary table or rotating table, is used for daily packaging on a small to medium scale. In this machine, the operator places the filled trays on the machine’s mold. The table is rotated by the operator, and according to pre-set settings on the machine, vacuuming, gas injection, and packaging are performed. While one side of the rotary table is packaging, the operator loads trays on the other side. After the packaging is completed, the table is rotated again by the operator, and the ejection system guides the trays from the mold upwards.

The semi-automatic tray sealer packaging machine is one of the products manufactured by Packen Company.

Machine Features:

- Suitable for low to medium packaging capacity

- Requires minimal space

- Affordable price and easy to use

- Various options available according to customer needs

- Capable of packaging using different methods such as MAP and others

Applications:

In addition to vegetables and greens, this machine can also package the following products:

- Various dry foods

- Various ready-to-eat cold foods

- Pickles (such as pickled cucumbers, olives) and pickled vegetables

- Various meat and protein products

- Fruits and various salads

- Packaging some dairy products such as cheese

- Bread and pastries

For more information, you can view the page on the semi-automatic tray sealer packaging machine.

Vacuum Chamber Packaging Machine

The vacuum chamber machine is used for packaging various food products, including vegetables and greens, in plastic bags or pouches. In the vacuum chamber machine, the level of vacuum and gas injection is fully controllable.

Machine Features:

Packaging products with vacuum or MAP method

Equipped with a rotary oil vacuum pump with very high suction power

Strong and error-free sealing

Applications:

In addition to vegetables and greens, this machine can also package the following items:

- Various dry foods

- Various ready-to-eat cold foods

- Pickled items (such as pickled cucumbers, olives) and pickles

- Various meat and protein products

- Fruits and various salads

- Packaging some dairy products such as cheese

For more information, you can visit the vacuum chamber packaging machine page.

Shrink Packaging Machine

This machine has a special mechanism that can cut the shrink film to the desired dimensions and length. Then, it places the separated pieces of vegetables and greens inside the film covering and uses a heating machine to heat it and create the shrink-wrapped package.

Thermoforming Packaging Machine

The thermoforming packaging machine from Packen Company is widely used in packaging many cosmetic and food products, including packaging vegetables and greens.

In this machine, plastic trays are made using various hard and soft films. The product is loaded into the trays by an operator or using a filler, and finally, vacuuming, gas injection, and sealing are performed.

Features of the Thermoforming Packaging Machine from Packen Company:

Easy to clean, stainless steel body, and resistant to corrosion and oxidation

Compatibility with various trays and products

Capability to install various fillers on the machine

Capability to install labelers and jet printers on the machine

Customer-requested options

Applications:

This machine can package the following items in addition to vegetables and greens:

- Various dry foods

- Various ready-to-eat cold foods (such as Olivier salad, pasta) and semi-prepared foods

- Pickled vegetables (such as pickled cucumbers, olives) and pickles

- Various meat and protein products

- Fruits and various salads

- Dairy products such as cheese

- Bread and pastries

- Various cosmetic products and medical equipment

For more information, you can visit the thermoforming packaging machine page.

Manual table top sealing machine

For packaging vegetables and greens at home, typically tabletop sealing machines, manual sealers, or manual shrink machines are used. These machines are not industrial and are affordably priced for home use and low capacities. There are also other machines such as tabletop vacuum sealers available for this purpose.

The tabletop sealing machine is used for packaging vegetables and greens in plastic trays at low capacities. The operator places the filled trays on the machine, put the film over the tray, pulls the lever down, and the packaging is completed. This machine also has the capability to use printed film.

In the manual sealing method, which is a simple and efficient technique for home use, the desired plastic bag for packaging is first selected. Then, the vegetables or greens are placed in the special plastic bag, and finally, the bag’s opening is placed under the machine and sealed.

If your capacity is high, you should naturally use machines that fall into the industrial or semi-industrial categories, which will be discussed further below.

Packaging Containers

Packaging containers for vegetables and greens can be designed in various shapes and sizes, but typically, several types of containers are used for packaging vegetables, including:

- Plastic Containers (PP): These containers provide manufacturers with the flexibility to use containers of different dimensions and shapes, distinguishing their packaging from others in the market. Additionally, plastic containers allow for packaging vegetables using the modified atmosphere packaging method.

- Boxes: Various boxes with different sizes and appearances are used for packaging vegetables. These boxes are usually made of cardboard.

- Cans: Plastic, glass, or metal cans can be used for packaging vegetables.

- Bags: Plastic or nylon bags are also used for packaging vegetables and greens.

Packaging vegetables and greens using these containers can be done in various forms, but the main goal is to preserve the quality and freshness of the products. Each type of packaging has its own unique features that may be used based on different societal needs and market conditions.

Containers with attractive shapes can enhance the presentation of vegetable packaging and have an impact on sales. Packen, with its expertise in the packaging machinery industry, can provide customers with customized molds for different containers.

Therefore, customers who need unique-shaped containers for packaging, rather than using common containers available in the market, can present their designs. At Packen, we create initial prototypes using 3D printers, and upon your approval as a customer, the mold is made, and the desired container is produced with your desired quantity.

You can consult with Packen regarding the selection of the best container for vegetables packaging and acquire your suitable container at the best price.

Types of Films Used in Packaging

Since we, at Packen, specialize in packaging various food products, medical devices, and pet foods, we can provide you with the necessary information on how to select the appropriate type of film and packaging container for vegetable. You can consult with our experienced experts and obtain the desired film and container at the best possible price.

The types of films used in vegetable packaging include: ordinary 2-layer films, multilayer barrier films, metallized films, aluminum films, skin pack films, anti-fog films, and others.

Packen offers trays with various materials for food products, medical devices and pet foods.

The Price of Vegetable and Greens Packaging Machines

The price of packaging machines in this field depends on the following factors:

- Type of machine

- Level of customization

- Tray dimensions

- Parts used in the machine

- Auxiliary equipment requested by the customer

Naturally, as machines become more automated, they include additional modules and their prices increase. For setting up a production line and purchasing a vegetable packaging machine, you can consult with our experts. We can provide the necessary advice on setting up the production line and determining which option is best for your needs, so you can choose the most suitable machine at the best price.